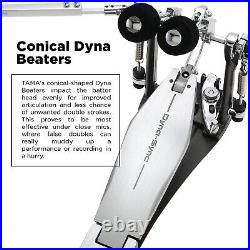

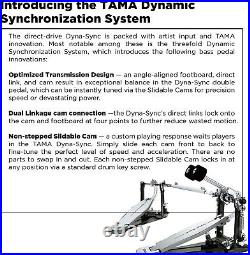

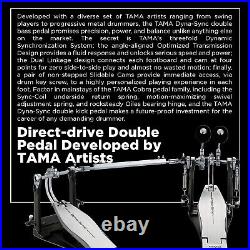

TAMA Dyna-Sync Drum Pedal. HPDS1TW (Dyna-Sync Twin Pedal). The HPDS1TW is a twin pedal that uses the “direct drive” method of connecting the cam and footboard with a metal arm on both the left and right side. By setting the contact point of the direct link connecting the cam and footboard at the optimum position and angle, we have sought the perfect balance between “power and speed” and natural feel. The cam turning radius can be adjusted “steplessly” by sliding the upper cam arm back and forth. This allows you to change the feel of the cam to suit your preference, providing a sense of unity that fits all styles of playing. A dedicated hard case is included. The direct drive design, which uses a metal arm to connect the cam to the footboard, eliminates “play” in the playing action, resulting in a very light footstep and quick return of the footboard. The Dyna-Sync pedal is not affected by the angle at which the footboard is stepped on, but the contact point of the direct link between the cam and the footboard can be set to the optimum position and angle to provide “power and speed” in addition to “power and speed”. The perfect balance between “power and speed” and “natural feel” is sought. In order to convert the footboard’s foot pressure into cam rotation without waste, a rotating shaft with bearings is mounted on both ends of the joint between the cam and the footboard. The two arms hold the cam and footboard together with equal force from both sides, preventing energy loss at the linkage to the utmost limit and realizing amazing response speed and power. By sliding the upper arm of the cam back and forth, the turning radius of the cam can be adjusted steplessly. When the arm is extended to increase the turning radius (moving in the direction of L: Large), the footboard angle and force required to step on the footboard during play will change more slowly, allowing for high operability with a fine touch like that of a chain drive pedal. Conversely, when the arm is retracted to a smaller size (moved toward S:Small), the footboard angle and the force required to step on the footboard change more, resulting in a more direct drive action with a solid step feel. This direct-drive action can be changed to various types of footsteps according to your preference, providing a sense of unity that fits all styles of playing. The Dyna-Sync pedals feature a new and unique footboard angle adjustment feature that is independent of the beater angle. The footboard has a clamp at the end of the footboard that connects the linkage extending from the cam, and by adjusting the bolt on the clamp with the tuning key, the angle of the entire footboard can be changed and secured firmly in place. The beater angle is infinitely adjustable in conjunction with the footboard. Loosen the square-headed bolt on the side of the rocker cam and adjust the angle using the scale on the black cap as a guide. The Dyna-Sync pedal uses an adjustment mechanism that changes the angle of the direct link in conjunction with the beater angle adjustment in order to maintain the characteristic pedal feel regardless of the beater angle. Therefore, when the beater angle is adjusted, the footboard angle will also change, so please adjust the angle of the footboard only by loosening the bolt on the clamp at the end of the footboard. The left beater angle of twin pedals should be adjusted by using the rocker cam, not the beater holder, in the same way. Sync-Coil is TAMA’s original mechanism that assists the return of the footboard by touching the coil to the backside of the footboard just before the beater hits the head. It uses a spring that is 1.5 times stronger than the Cobra Coil of the Cobra pedal, for a more powerful effect. Traditional bale beater with black felt and slightly tapered shape. The Dyna-Beater provides a natural feeling when playing and a clear, dynamic bass drum sound. A spring (HP900-7H) with stronger tension than that used in the IRON COBRA 900/600 pedals is used. A mechanism to maximize the effect of the spring. By rotating the shaft that holds the lower end of the spring, the spring always expands and contracts vertically without distortion, even during violent movements. This converts the elastic energy stored in the spring into energy that moves the pedal without loss. Furthermore, by reducing friction on the spring connection, the ideal pedal work is achieved, with light pressure and quick return. Speedo-ring & Quick Hook. A high-precision ball bearing is provided at the connection between the spring and the shaft. This bearing converts the elastic energy generated in the spring when the footboard is depressed into rotational energy of the cam without waste. The ball bearing also follows the movement of the spring precisely, so that the movement of the foot and the footboard are in tandem. TAMA’s original clamp that securely holds bass drum hoops of various thicknesses. The tip of the clamp is rubber-mounted to improve grip and hold the bass drum hoop in place while minimizing damage to the hoop. The clamp also features a three-dimensional tip structure, so even in setups where the front side of the bass drum is extremely floated, the tip fits the angle of the hoop to stabilize the pedal. The footboard for the Dyna-Sync pedal is designed to be flat across its entire surface to accommodate a variety of pedal techniques. In addition, while the footboard itself is of standard length, the starting point of the footboard is set back to a point where it can be “light” without discomfort, thereby maintaining a natural action and light stepping. By stepping on the heel side, which has less vertical movement distance, like a long footboard, the ability to respond to fast passages can be increased. The bearings at both ends of the hinge shaft are held between the top and bottom to distribute the force applied to the bearings when the pedals are pressed. This reduces the load on the hinge shaft itself, resulting in more precise rotation and smoother operation with higher durability. The hinge, which is the fulcrum of the footboard, uses “Oiles” bearings made of Bellbrass mesh coated with Teflon resin. This prevents the footboard from shaking sideways and provides smooth pedal work. Economy:Japan post (without tracking). Standard:EMS 5-10days (with tracking). Due to Japanese Post Service delay, estimated arrival time can be delay. Depends on custom in your country also. International Buyers – Please Note. We do not mark merchandise values below value or mark items as gifts – US and International government regulations prohibit such behavior. Thank you for your understanding.